The design of new engineering materials resistant to both wear damage and corrosion degradation becomes increasingly demanding in complex service conditions. Unfortunately, there is typically a tradeoff between wear and corrosion resistance, even for important passive metals such as Al alloys. This is due to the presence of precipitates which hardens the material but at the same time lead to unfavorable galvanic coupling between the precipitates and the matrix, resulting in accelerated corrosion. The formation of supersaturated solid solution using non-equilibrium methods such as physical vapor deposition and electrodeposition enhances the corrosion and tribocorrosion resistance of these alloys without compromising their strength.

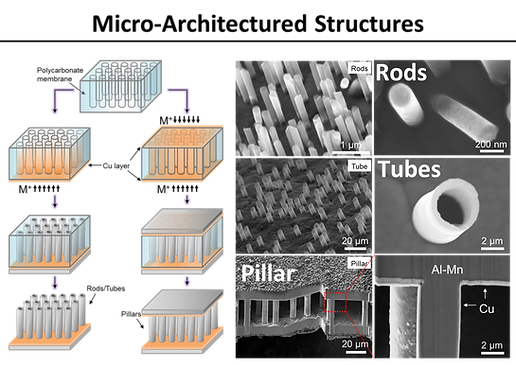

Micro-architectured materials including microlattices and microsandwiches have emerged recently as promising structural and functional frameworks for small-scale multi-functional devices. Their open architecture not only leads to low areal density and high damage tolerance, but also provides channels for heat/fluid flow, which is critical to multi-functional devices such as high-capacity batteries, insect-like robots, and micro-air vehicles. A sandwich structure exhibits higher bending rigidity than lattices by effectively redistributing the mass to the outer surfaces (instead of the core), similar to natural cellular materials found in insects and plants. The stiff face sheets carry bending and in-plane stresses during deformation, while the low-density core bears transverse shear stresses.

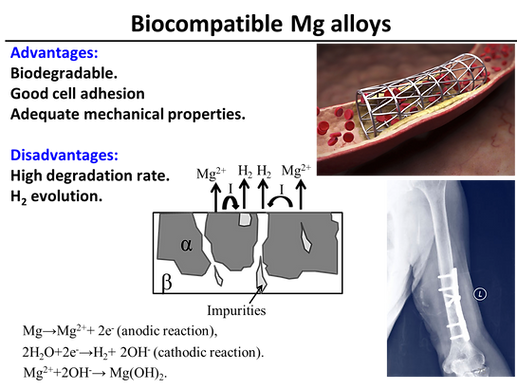

Biodegradable WE43 magnesium alloy containing major alloying elements of yttrium, neodymium, and zirconium has received great interest lately for potential applications as cardiovascular stents and bone implants. WE43 Mg alloys exhibit good cell adhesion in physiological environment and can safely degrade in the human body; hence no post operation is required once the damaged tissue is healed, minimizing procedure cost and risks. In contrast to conventional medical metals such as titanium, cobalt-chromium, and stainless steel, the mechanical properties of Mg are close to that of human bones, thus minimizing the stress shield effect and increasing implant stability. Moreover, Mg is an essential element for human metabolic processes and has been shown to enhance bone growth when used as implants. Unfortunately, the high degradation rate of Mg alloys in physiological environments and subsequent loss of structural integrity and extensive hydrogen evolution to balance the anodic dissolution, limits the wide applications of these materials.

Post-Tensioned Tendons are used in segmentally constructed bridges to hold the structure together allowing the use of longer spans with less deflection, thinner sections, heavier load capacities, less construction periods, and ultimately reducing the cost of constructions when compared to the conventional reinforced structures. The high strength steel strands are placed inside high density polyethylene ducts, which prevent the intrusion of water and aggressive chemicals and filled with chloride free cement grout, which protects the steel from corrosion by maintaining an alkaline environment. In some instances, severe corrosion distress and even complete failure of post tensioned tendons have been reported. These failures were attributed to local grout deficiencies in the form of voids due to bleed water, intrusion of external chloride and water through anchorages or defects in the ducts, and carbonation of the grout. Strand failures were found to occur at locations close to the anchorage due to galvanic coupling between different metals in the anchorage system. Immediate repair of tendons undergoing corrosion is mandatory practice as these tendons are critical structural components where the integrity of the bridges depends on the large tensile load concentration by the tendon. Recently, a cost-effective corrosion mitigation technique by tendon impregnation, a promising procedure recently developed to protect both new and existing post tensioned tendons, is implemented allowing the extension of the service life of bridges having grout defects such as segregation, soft grout, chloride contamination and voids.